ROMI ES Series

Plastic Injection Moulding Machines

ROMI ES Series

Presentation

The ROMI ES 300 hybrid injection moulding machine was developed to make plastic parts that require high injection rate, maximum precision and ultra-fast cycles with the lowest energy consumption.

- Larger mould area: 730 x 730 mm

- Injection rate: 3,850 cm³ (1,000 m/s)

- Full overlap of movements. Save up to 30% in the cycle times.

- Higher plasticising capacity: 110 g/s (PS)

- Dry cycle: 1.9 s

- Water-cooled torque motor during plasticising process.

- Up to 80% reduction in heat generation.

- High accuracy of all movements due to the use of optical encoder and high precision servomotors.

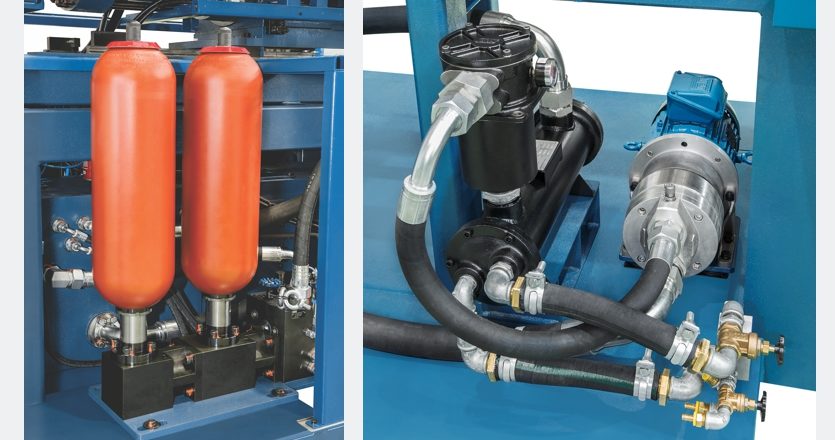

- Offline system for filtering, providing longer service life and efficiency for the hydraulic system.

- Movements on the clamping and extraction units through servomotors.

- Moog servo valve for injection control

- Pressure accumulators for high speed injection

ROMI ES Series

Main Technical Features

| ROMI ES 300 | ||

|---|---|---|

| Controlmaster | - | CM20 multitouch 19'' Full HD |

| Mould clamping force | t | 300 |

| Maximum opening stroke | mm | 650 |

| Mould height (maximum x minimum) | mm | 730 x 200 |

| Space between columns (horiz. x vert.) | mm | 730 x 730 |

ROMI ES Series

Catalogues

ROMI ES Series

Videos

Consult an expert

Need more information about this product? Send a request or call us on +003455453455